What are the common faults of board frame filter machines? How to solve it?

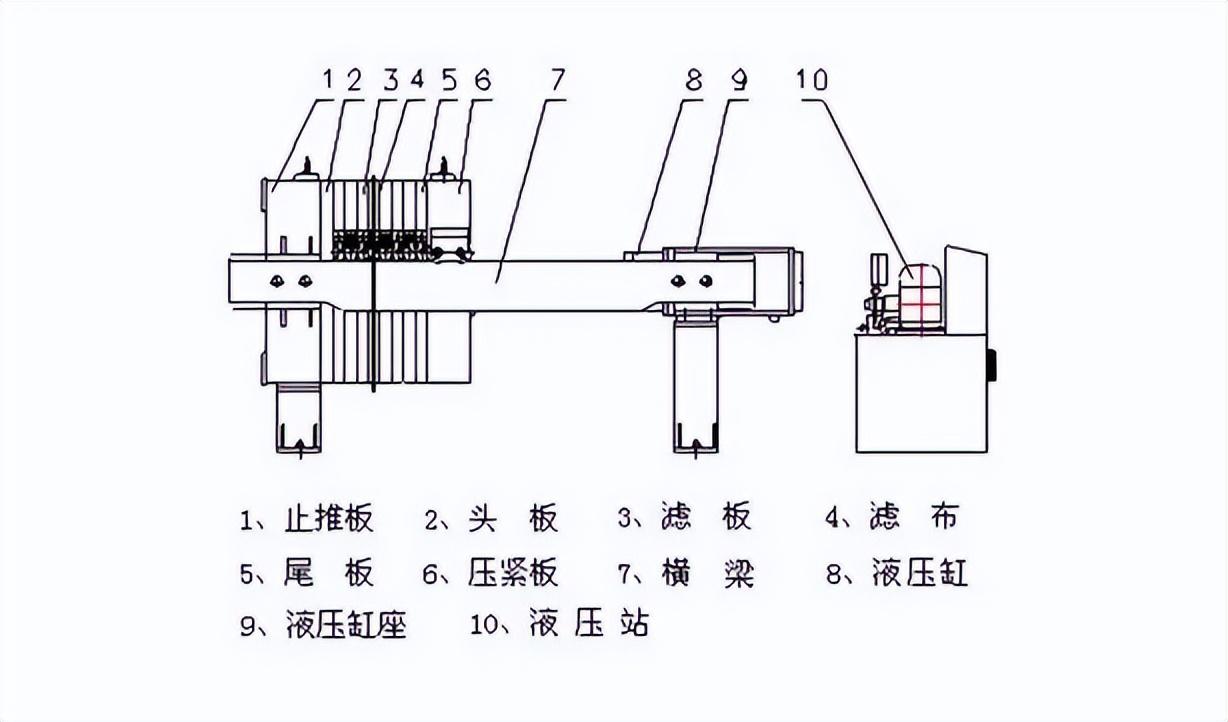

The plate frame filter machine is a processing equipment for sludge in the sewage treatment system. It is a commonly used equipment in the sludge treatment process. It consists of five parts, namely the filter frame, the hydraulic system, the electrical system, the filter plate, and Filter plate transmission system. The working principle is relatively simple. First of all, the hydraulic force is compressed to the plate frame. The precipitated sludge enters from the middle and is distributed between the filter cloth. Due to the tightness of the plate frame, the sludge cannot overflow. In the lower, the water in the sludge seeps out from the filter cloth and flows into the water pipe, and the mud cake is left in the cavity. After the plate frame is unloaded, the filter plate is opened, and the mud cake rely on the gravity. Work.

So what are the common faults? Xiao Bian has compiled a few questions about the private messages of everyone in the background. Let's take a look together ~

What should I do if I can't open the filter board?

When the filter after blowing is loosened, the filter board often does not open or stops intermittently. At this time, the filter board must be released to meet the pressure standards. Once the pressure is not completely leaked, the filter plate will release the problem with the problem with the operation. If the system fails to supplement the hydraulic oil in time due to excessive loss during the long -term operation, the system will insufficient oil supply, resulting in poor continuous hydraulic cylinder and intermittent stopping phenomenon.

What are the easy accessories of the plate frame filter equipment?

Filter cloth, water mouth, O -type circle, and sealing circle are relatively common damaged parts. According to the usage, you can replace it in time. In order to ensure the normal operation of the equipment, we can buy these accessories at the original manufacturer when purchasing the equipment. In this way, we can avoid the delayed delay work progress of accessories.

What are the reasons for spraying between the filters?

The filter board itself has been damaged or the cover of the filter plate has been connected to the groove; the pressure gauge is not installed on the feed pipe, which causes the feed pressure to be out of control and eventually cause the spray. After the plate pressure is tight, the gap is large; the top pressure of the filter plate is insufficient. After the feeding pressure is increased, the effect of the filter plate will open the filter plate to cause the spray.

News

Da Zhang Environmental Protection was rated as the best nati

Da Zhang Filtration will meet you at the largest environment

Dazhang Company conducts safety education to improve employe

How does a diaphragm filter press deal with sewage?

Dazhang Company carries out integrity training activities

Zhang Zhenli: Filtering out green mountains and clear waters